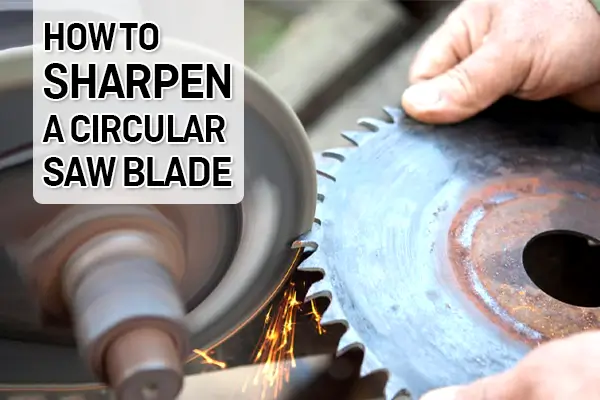

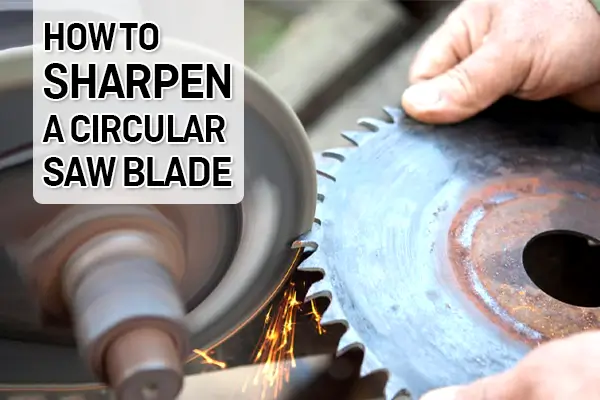

How often have you felt the need to know how to sharpen a circular saw blade? If you are a professional woodworker, your answer will be many times. Here are the most workable tips on this topic.

Circular saw is one of the essential cutting tools for a woodworker. The more extensively it is used, the more you will need to sharpen its blade. With regular usage, the blade is worn out. As a result, its cutting quality is not like a new one.

A worn-out blade is no use to a professional or even a DIYer. So, the only option is to change or sharpen it as we know that a new blade is quite pricey. So, the best option will be to sharpen the one in use.

In addition to work loss, an old blade can also cause a fatal accident. Moreover, it can overheat due to continuous work. In that case, it will burn and damage the stock. Hence, blade changing or circular saw sharpening at the right time is more than essential.

Some of our readers might be thinking that you must be an expert to do that. Well, it is half true. It needs somewhat expertise, but it is only at the initial level. Once you get proficient in that process, it will just be one of the most manageable tasks you have ever done. After that, if anyone asks you, can circular saw blades be sharpened? Your answer will be a big Yes.

Tools and Techniques Required for Sharpening a Circular Saw Blade

First, you will need a complete set of tools and specific training to sharpen circular saw blade. There are many tools available in the market that you can use for this purpose. So naturally, their prices vary from low to high according to their functionality. We recommend that you start with relatively economical solutions.

| 🔹 2 strong metallic clamps (screw type) | 🔹 2 pliers |

| 🔹2 large files (one flat & the other triangular) | 🔹 A circular spanner |

Step by Step Guide on Circular Saw Blade Sharpening

Now comes the turn of sharpening the blade. It is a step-wise process. You must perform all the steps systemically. You can neither miss any step nor change the sequence. So, what are we waiting for? Let us start with the circular saw’s blade sharpening process.

STEP 1: Remove the Blade with Great Caution

Before starting the sharpening, remove the blade from the saw with utmost care. It is the safest way to sharpen it without getting hurt. Most of the latest designs of circular saws have an eject button for that purpose. It makes your job less complicated.

STEP 2: Secure and Fix the Blade for Safety

After removing the blade, clean it with a soft cloth and fix it on a workbench. The teeth must be in your direction. For fixation, you will have to use the two clamps. However, do not tighten the clamps so tightly that it becomes difficult for you to loosen them.

STEP 3: Mark the Starting Point

Before properly starting the honing, mark the spot where you want to start it. It will act as the starting point for your sharpening process. Then, it will help you cover your progress as you proceed. Also, thus you will know where to end the process.

Once you are done with the sharpening, the starting point will also be the ending point. So even if someone asks you how to sharpen a circular saw blade, you can guide that person that way.

How To Sharpen Circular Saw Blade Using An Angle Grinder:

STEP 4: Filing the Blade Sharp

Now comes the turn of filing the blade’s edges. Again, there is no rocket science in it. All the task depends on holding and moving the file on the edges. The angle is quite crucial in this regard. You usually have to follow the same slope a blade has on it.

To be more precise, study the manual or handbook provided with the circular saw. It will help you understand the angle of your blade. Once you have an idea of the angle, the easier it will be to complete the task. Now all you have to do is apply proper strokes.

STEP 5: Install the Blade

After you are done with the filing, next comes the last stage of installation. Fixing it back is usually easier than removing it. All the processes will be in the same sequence you did from scratch.

Once the blade is back in its socket, do not run the circular saw until and unless you are entirely sure that you have fixed it well. If the blade is loose, it might fly out of its place and cause a fatal accident. That is why one must take good care of this last stage.

How You Can Sharpen A Saw Blade by Hand

Why shall you sharpen a circular saw blade?

As mentioned previously, a circular saw blade is not a low-priced item. Therefore, few craftsmen can afford to change or replace it. That is why professional woodworkers prefer to sharpen it most of the time. However, that process two has some limitations.

For instance, one cannot do the honing more than 3 to 4 times. After that, the edges of the blade would lose their built-in bevel. In other words, the metal will be so much worn out that it will no more be able to pass through that process.

And that will be the stage when you will have to replace the blade at any cost. Also, certain blade types have carbide tips that will wear out due to continuous filing. So, in that case too, you will have to replace them.

How to Know That a Blade is Worn-Out?

Only a professional woodworker or craftsman can tell when a circular saw blade and dull enough. However, in some cases, the change is quite apparent. For instance, if the blade is damaged or broken, anyone can tell it is time to replace it.

Typically, carbide-tipped blades are replaceable when they lose their carbide coating on the edges. However, even a DIYer can tell when a blade has lost its carbide. Other indications of a worn-out blade are as follows:

- The blade will certainly cut or reduce far slower than typical or might entirely bind mid-cut.

- It will develop more rips or cracking than typical, especially on the wooden stock.

- The blade will certainly leave ugly marks on the timber and might burn it due to overheating.

- It will undoubtedly look smooth, which shows that rubies (in case it is diamond coated) have deteriorated.

Regardless of carbide or steel blades, it has an expiry proportional to the number of cuts it inflicts on the stock. Therefore, professionals typically maintain a record of their work to know precisely how many cuts to change the blade.

If you neglect the points mentioned above, it can lead to poor performance of your circular saw.

How to Extend Circular Saw Blade’s Life Span

Depending on the blade you’re employing, you can clean up, hone or change it. Most of the carbide-tipped blades need a slight cleansing procedure, and they are just like new again. But that is if you have once or twice used a brand-new blade.

Generally, a worn-out carbide-tipped or steel-tipped blade is simply unclean if it is not working well. Just clean it and check the performance. If it is not altered, use it as long as the same problem is repeated.

Precautionary Measures to keep in Mind Before Blade Sharpening

🔹 We all know that the blade is still sharp enough to cut your hands, which is why you must treat a worn-out blade more than carefully.

🔹 Always use the right tools recommended by experts to sharpen the blades.

🔹 Wear safety goggles and gloves while working with the file. There might be wooden or metal traces that can injure your eyes or hands .

🔹 Sharpen the blade in a well-lit place. It will save you from any accident.

A blade is the essential part of a circular saw. However, it can wear out due to continuous use and thus get blunt. In that case, one has to either change or sharpen it. As the blade is quite costly, it is always feasible to sharpen it. There are many techniques on how to sharpen a circular saw blade, but the one done with the file done manually is the most accurate and workable. It depends upon the structure of the blade in use. For instance, a carbide blade can be sharpened 3 to 4 times. In the same way, a good-quality regular steel blade can be sharpened as long as the teeth are not entirely flat. Of course, it is beneficial both economically and technically. A new blade costs a handsome amount. Until your blade is completely worn out, it is recommended to sharpen it. That is why “how to sharpen a circular saw blade” has become a popular query on the internet. If you keep it clean and lubricated regularly, it will last long. Also, the usage and work style are directly related to the life span of a circular saw blade. A file, set of clamps, and a benchtop table are the essential tools used for that purpose.Conclusion

FAQs

Q: How many times can we sharpen a Circular saw blade?

Q: Is it worth sharpening circular saw blades?

Q: How can a circular saw blade last long?

Q: Through which tools can you sharpen circular saw blades?